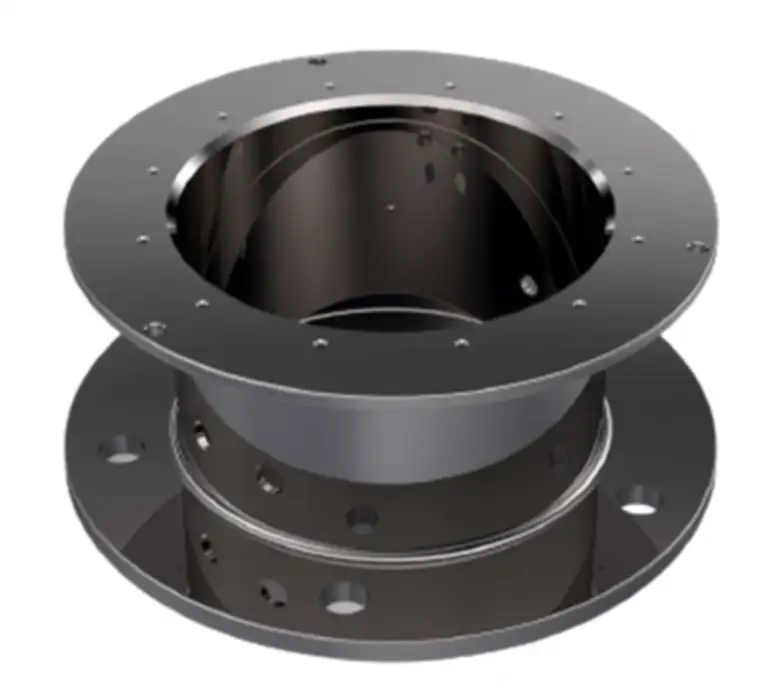

Case Study: Deck Assembly

Before coming to Investment casting, the customer was made machined flanges and machined pipes are welded together and needed an integrated part without welding

Project Overview

Application

Marine Industry, Part Weight: 6.8 Kgs

Focus Area

To increase the productivity and Quality

Challenge

The customer was receiving an inconsistent supply of parts. The quality was not repeatable and ultimately, not fit for purpose.

The Problem

The customer was receiving an inconsistent supply of parts. The quality was not repeatable and ultimately, not fit for purpose.

Our Solution

SAN Precision Alloys unique process optimization techniques combine with our expert Cross Functional Team helped to eliminate the welding process to increase the productivity and to be used for the manufacture of this component. To Integrated of Pipe, top and bottom flanges made as single in wax tree assembly. We were able to identify risk areas (Welding, Concentricity) with the casting and machining process requirements, and mitigate them with solutions ahead of time. This ensured that we were able to produce parts that were fit for purpose and more importantly in a repeatable Manner.