Case Study: Rear Axle Shaft

The customer requested an integrated item without welding and had previously manufactured a machined shaft and machined disc that were welded together

Project Overview

Application

Automotive Industry, Part Weight: 2.5 Kgs

Focus Area

To meet the tight limits on dimension tolerance as per customer print

Challenge

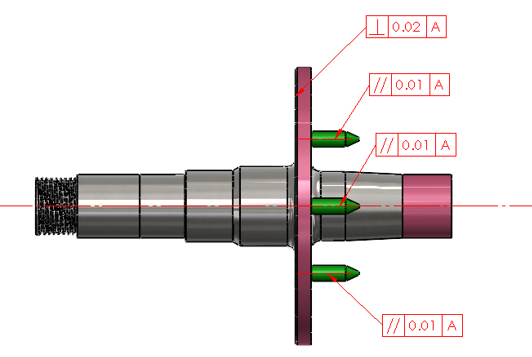

The shaft and disc are welded together during assembly, which causes deformation. Because of this, it was unable to achieve the requirements for the shaft's and disc's concentricity and perpendicularity (0.02 mm)

The Problem

The shaft and disc are welded together during assembly, which causes deformation. Because of this, it was unable to achieve the requirements for the shaft's and disc's concentricity and perpendicularity (0.02 mm)

Our Solution

SAN Precision Alloys’ unique process optimization methods and the knowledge of our Cross Functional Team, we were able to eliminate the welding step in order to meet the component’s quality criteria and increase the productivity. During wax tree assembly, the shaft and disc were combined into a single component. With the help of the casting and machining process requirements, we were able to pinpoint risk areas (welding, perpendicularity, and concentration) and minimize them with solutions in advance. This made it possible for us to make parts that were suitable for their intended use and more significantly in a repeatable way.

Impact

Besides the technical challenges, SAN Precision Alloys’ expertise in both the new product development and process development teams allowed castings to be manufactured to meet the exacting requirements of the clients. As a result, SAN Precision Alloys was able to offer a technically challenging part at a competitive price for use in the demanding automotive sectors.

Key Benefits

To Eliminate the welding process

To meet the tight dimension as per customer requirements

Reduce the rejection

Increase the productivity

To eliminate additional process of stress relieving

Less Material cost and material handling